Exploring the Future: **China Prototype Manufacturing** and Its Impact on Global Industries

Understanding China Prototype Manufacturing

In today’s fast-paced market, the concept of China prototype manufacturing has become a cornerstone for companies looking to innovate and streamline their product development processes. This practice allows businesses to transform their ideas into tangible products swiftly and efficiently, providing them with a competitive edge in their respective industries.

With the global landscape continuously evolving, manufacturers in China have developed robust systems and technologies that enhance the quality of prototypes, reduce production time, and decrease overall costs. These advancements are essential for businesses that aim to remain at the forefront of innovation.

The Advantages of Choosing China for Prototype Manufacturing

Opting for China prototype manufacturing offers myriad benefits. Here are some of the most significant advantages:

- Cost-Effectiveness: One of the primary reasons businesses choose manufacturers in China is the lower cost of labor and materials. This affordability enables companies to allocate their resources to other critical areas.

- Rapid Turnaround Times: Chinese manufacturers are renowned for their capability to produce prototypes swiftly. This speed ensures that products can go to market faster.

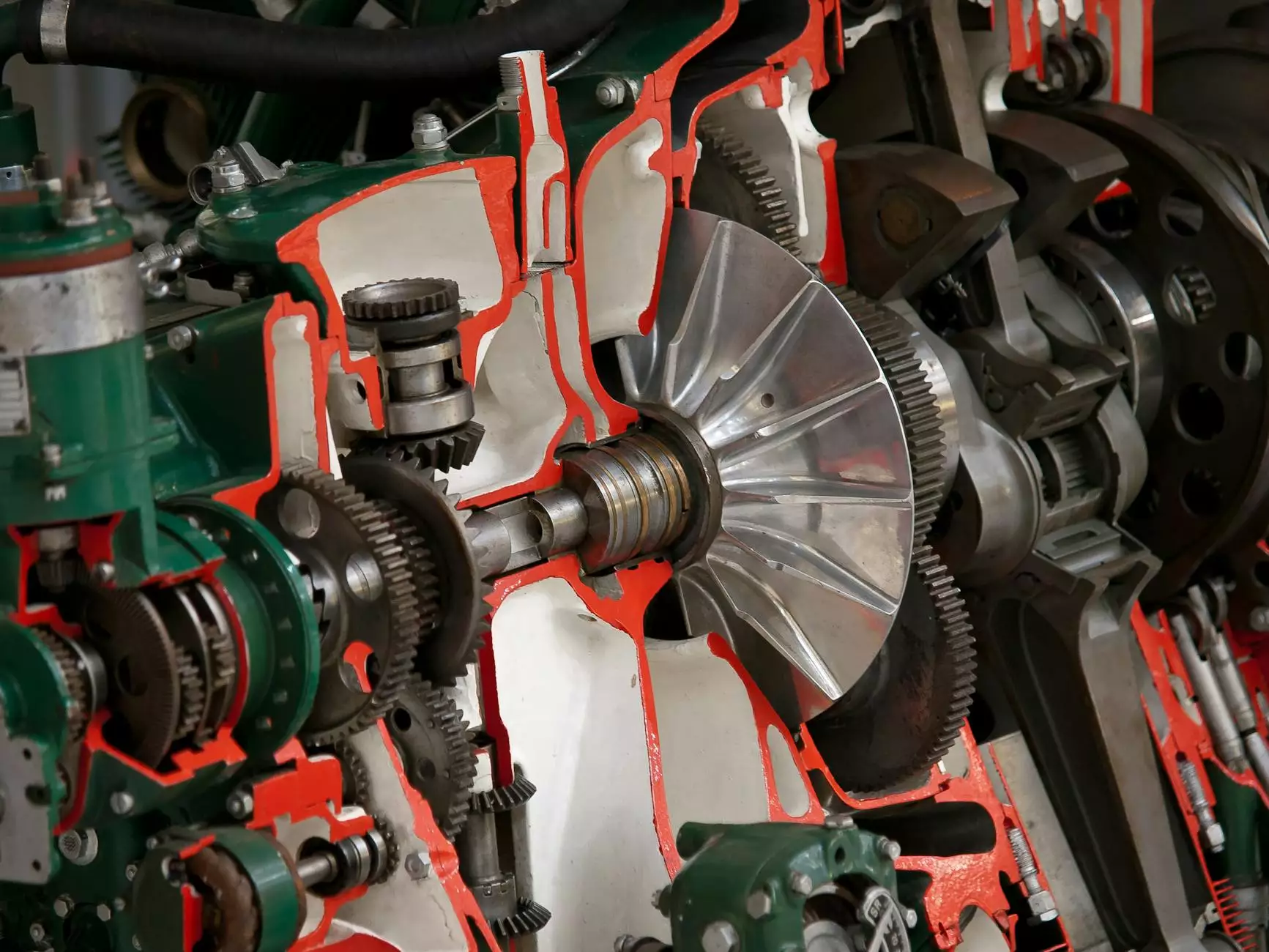

- Advanced Technology: Many Chinese firms employ state-of-the-art machinery and technology, which enhances the precision and quality of prototypes.

- Skilled Workforce: China boasts a vast pool of skilled labor that is experienced in various manufacturing processes, including metal fabrication, making it easier to find specialized expertise.

Common Materials Used in China Prototype Manufacturing

Another critical aspect of China prototype manufacturing is the variety of materials available for prototyping. Manufacturers provide access to a range of materials that cater to diverse project requirements:

- Metals: Common choices include aluminum, stainless steel, and brass. Each metal has unique properties that make it suitable for different applications.

- Plastics: Various types of plastic, including ABS, PLA, and Nylon, are widely used due to their versatility and ease of processing.

- Composites: Advanced materials like carbon fiber and fiberglass offer lightweight and durable options for high-performance prototypes.

The Process of China Prototype Manufacturing

The process of prototyping in China involves several crucial steps, ensuring that each project progresses smoothly from concept to realization. Here's how it typically works:

1. Concept Development

Every project begins with an idea. The development of a prototype starts with a clear understanding of the product concept. Stakeholders collaborate to define the project requirements and specifications.

2. Design and Engineering

Utilizing CAD (Computer-Aided Design) software, engineers create 3D models of the prototype. This design phase is critical as it sets the foundation for the physical product.

3. Prototyping Methods

Depending on the project requirements, different prototyping methods may be employed, including:

- CNC Machining: Ideal for creating parts from solid blocks of material, offering high precision.

- 3D Printing: A fast and flexible method that allows for quick iterations and complex geometries.

- Injection Molding: Suitable for mass production of plastic parts once the prototype is validated, although it requires a larger initial investment.

4. Testing and Evaluation

After the prototype is manufactured, rigorous testing is conducted to evaluate its performance against specifications. This feedback is crucial for making necessary adjustments.

5. Final Adjustments

Based on testing results, modifications can be made to optimize the prototype before moving to mass production.

Quality Control in China Prototype Manufacturing

Quality control is a significant element in China prototype manufacturing. Manufacturers implement various quality assurance methodologies to ensure that every prototype meets specific standards. Some of these include:

- ISO Certification: Many manufacturers adhere to ISO standards, guaranteeing a high level of quality in their processes.

- Iteration Testing: Continuous testing during the production process allows for immediate identification and rectification of any issues.

- 3rd Party Inspections: Engaging external inspectors provides an unbiased evaluation of the prototype quality.

Innovative Technologies Driving China Prototype Manufacturing

The landscape of prototype manufacturing is continuously evolving, primarily due to technological advancements. Some innovative technologies leading the way include:

1. Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, has revolutionized the prototyping process. It allows manufacturers to create complex structures layer by layer, significantly reducing material waste and time.

2. Advanced CNC Machinery

State-of-the-art CNC machines provide unparalleled precision in metal fabrication. These machines can automate processes and reduce human error, leading to superior prototype quality.

3. Digital Twin Technology

Digital twin technology involves creating a virtual model of the physical prototype. This allows for real-time monitoring and adjustments, greatly enhancing the efficiency of the manufacturing process.

Choosing the Right Partner for China Prototype Manufacturing

Selecting the right manufacturing partner is crucial for the success of any project. Companies should consider the following factors when choosing a China prototype manufacturing partner:

- Experience and Expertise: Assess the industry experience and technical expertise of the manufacturer in producing similar prototypes.

- Portfolio of Work: Reviewing the manufacturer’s portfolio can give insights into their design capabilities and quality.

- Communication: Effective communication is essential for collaboration. Ensure that the manufacturer is responsive and open to discussion.

- Customization Capabilities: Look for manufacturers that offer tailored solutions to meet specific project requirements.

Future Trends in China Prototype Manufacturing

The future of China prototype manufacturing is bright, with several emerging trends that promise to reshape the industry:

1. Increased Automation

Automation technologies will likely play a more prominent role, enhancing manufacturing efficiency and consistency.

2. Sustainable Practices

As global awareness of environmental issues grows, manufacturers are adopting sustainable practices, such as reducing waste and using eco-friendly materials.

3. Integration of AI and Machine Learning

AI-driven tools can analyze data and optimize manufacturing processes, leading to smarter production systems capable of making real-time adjustments.

4. Remote Collaboration Tools

The rise of remote work and digital collaboration tools will facilitate better communication between teams across the globe, streamlining the prototyping process.

Conclusion

The realm of China prototype manufacturing is not just a trend; it's a transformative approach that supports businesses in realizing their product visions efficiently and cost-effectively. By leveraging advanced technologies, skilled labor, and comprehensive quality control, manufacturers like DeepMould are poised to lead the charge in helping companies innovate and succeed. As the industry continues to evolve, businesses must stay informed and agile to capitalize on the vast opportunities presented by China’s manufacturing landscape.